Berner Torantriebe stands for sustainability

Our motivation: Sustainability

Our actions: CO2-neutral

Berner Torantriebe KG is a forward-looking company that focuses its activities on manufacturing excellent products that are sustainable and durable.

For us, this means not only developing innovative solutions, but also treating our environment and its resources with care. We want to leave behind an intact environment that is worth living in for future generations.

The Berner company has been carbon neutral since the beginning of 2022!

Berner Torantriebe complies with the five steps of climate action and is certified by ClimatePartner. The ClimatePartner certification provides transparent disclosure of a company’s entire climate strategy, including its carbon footprint, reduction targets, implemented reductions, and financial contributions to climate protection projects worldwide.

Calculate

By calculating our CO2 emissions annually, we know exactly where we stand, where CO2 emissions originate, and how they can be avoided.

Reduce

Our goal is to avoid or reduce CO2 emissions. We pursue this goal wherever possible. Through measures both large and small, we are helping to reduce our carbon footprint.

Compensate

We offset unavoidable CO2 emissions through compensation. We have decided to support projects for the expansion of wind energy in India and reforestation projects in Uruguay.

We also act responsibly in this area

We are continuously working to operate in a carbon-neutral manner and treat people and nature with respect. Every step, no matter how small, helps to shape a better future.

So join us!

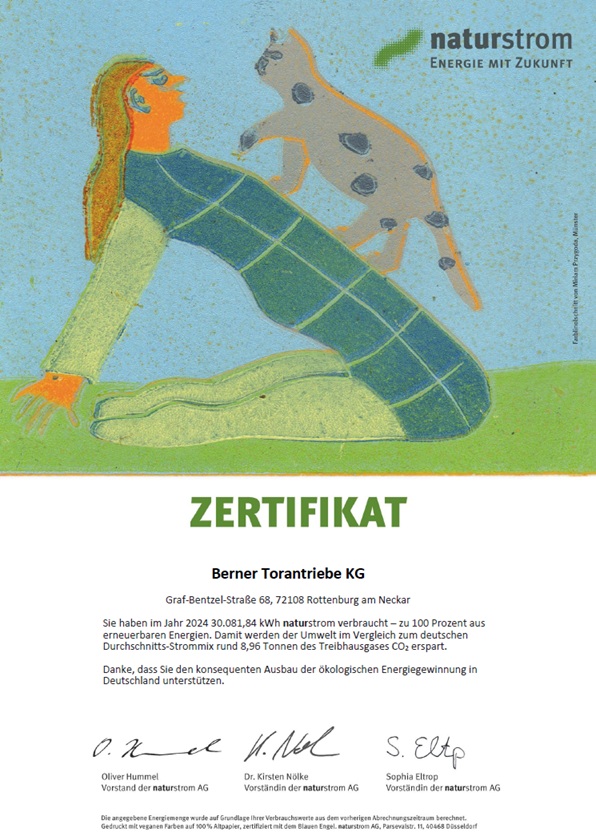

Since 2012, we have been sourcing 100% of our energy requirements from green electricity.

In 2023, this will enable us to save around 47.92 tons of CO2.

The use of green electricity sustainably improves our environmental and climate balance, significantly reduces CO2 emissions, and sets the right course for a clean future.

In addition, the use of green electricity supports the expansion of renewable energies and contributes to making energy production clean, safe, and sustainable for future generations.

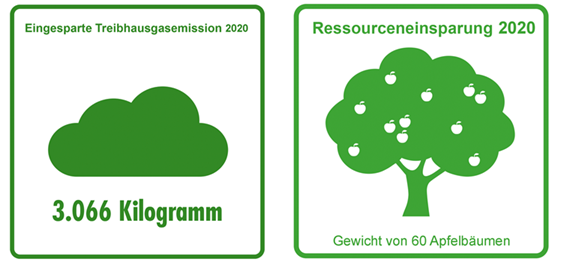

We have also decided to think ahead when it comes to packaging materials and are breaking new ground with the use of lightweight packaging made from paper, cardboard, and paperboard. Recycling the materials we use alone saved around 24,795 kilograms of resources and 3,210 kilograms of greenhouse gases in 2018.

With every step we take towards a better environmental balance, no matter how small, we raise awareness among all those involved of how important it is to work towards a healthy climate – sustainably and consistently.

With these and other measures, Berner is committed to improving the environment and will continue to consistently expand its efforts in this important area in the future.

Recycled paper is increasingly being used as a sustainable and economical alternative to conventional paper in companies and public institutions. That is why we have also decided to act in an ecologically and economically responsible manner and to use certified recycled paper for our daily communication and for printing assembly and operating instructions. Often it is only small things that make a difference to the environment.

As a team, we have decided to lower the room temperature to 19 degrees during the winter months, purchase beverages in reusable glass bottles, and, whenever possible, meet with business partners by train or via video conference.

Our drive generation is energy-optimized and saves up to 90% in energy costs per year.

0.5 W power consumption in standby mode ensures significantly reduced power consumption and costs effectively less than €2 per year. The drives are produced in Germany in a CO2-neutral manner.

Our aluminum entrance gates have been in use for decades. Aluminum is a low-maintenance, durable material that can be recycled with little energy expenditure and no loss of quality.

Aluminum is a particularly sustainable material, especially in end-of-life recycling.

Today, aluminum is primarily produced in an environmentally friendly manner using hydropower and is particularly sustainable in its end use. The lower limit for the service life of aluminum in the construction sector is 60 years. At the end of its life cycle, the vast majority (up to 95%) is recycled. According to the International Aluminum Institute, 75% of all aluminum ever produced has been reused to date.